Certifications

Our production sites are IFS Version 6 higher version and BRC grade A certified.

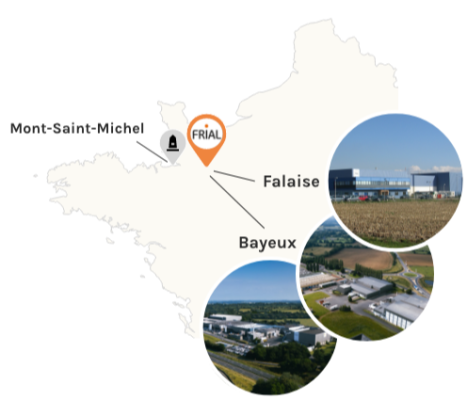

Frial establishes our first location in Bayeux, France

Expands production units for

seafood products

Launches our ready-made meals production site

Manufactures and lauches the first

microwaveable and recyclable cardboard tray

Launches the first enrobed Individual Quick Frozen portionable recipes

Creation of Frial’s integrated quality laboratory

Develops our sourcing initiative

Creates and launches

the first frozen sauce pellets

Constructs Frial’s first storage facility and

seafood packaging production line

Frial comes to America

and Frial Inc. is born

Expands to create our center for research

and development

Launches the first of our

“Clean Label” recipes

Receives Authorized Economic Operator (AEO) approval

Opens our third production site facility in Falaise, France

Frial obtains official certifications

Launches newest

sustainaible packagings

Frial releases our $28 million

investment plan

Acquisition of FRIAL by Le Duff Group

Quality laboratory renovation

Established in 1980

Creator and manufacturer of fresh frozen culinary solutions in private label. The company supports its partner clients, specialists retailers in frozen food, mass distribution, and Food Service through innovative and customizable solutions in seafood and single and sharable ready made meals.

Our production sites are IFS Version 6 higher version and BRC grade A certified.

Raw and enrobed seafood

Cutting, cooking, packaging

IQF ingredients enrobed with a sauce

Cooked entrees and sides

Bag : single serve, family and portionable

Cooked entrees

Tray or bowl

Single serve or family

Pellets / crowns Sauces, purées and soup

Bag or cardboard box

At Frial, delivering superior quality is central to our cultural values.

Our Commitment:

Regular checks all the way through the manufacturing steps

Innovation is driven by a diverse and multidisciplinary team of experts.

We combine the latest trends and advancements in sustainable packaging and our masterful culinary craft to offer top of the line solutions.

Natural, flavorful, and well-balanced recipes are at the core of what we do.We are a “Clean Label” partner, striving to limit the list of ingredients in our products.

Sourcing

Quality taste

Materials origin

Integrated sectors

12

Culinary specialists

Try the challenge of cooking with taste, as natural as possible

1

R&D dedicated area

Products and customers reception

3

Laboratories

1

Industrial testing dedicated area

+ 30 000

Pallets

Storage capabilities

+ 100 000

Pallets

Transfert/years

+ 1 000

Containers

Import / export